Mastering ISO 9001: How to create effective process maps

Effective process mapping for ISO 9001 certification

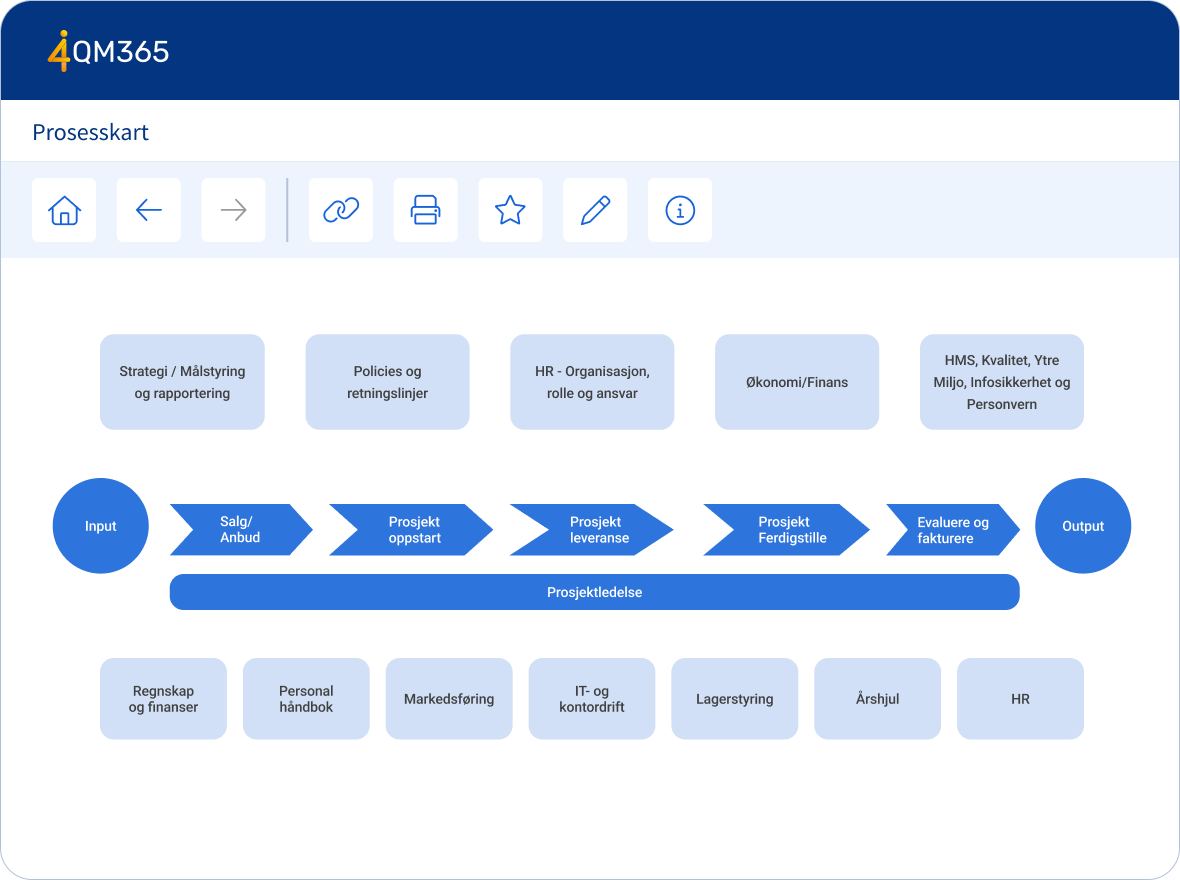

For many businesses, ISO 9001 certification represents an important milestone that signals a clear commitment to quality and customer satisfaction. A key part of ISO 9001 is process-based management, which requires clear and comprehensive process mapping. In this post, we take a closer look at how you can design effective process maps that both meet the requirements of ISO 9001 and provide employees with a clear understanding of your business operations.

Why is process mapping important?

Unlike traditional organizational charts, process charts show how the business functions as a dynamic system, illustrating the connections between customers, products and workflows. ISO 9001 places great emphasis on identifying and managing processes to meet customer expectations. Therefore, process mapping is not just recommended – it is a necessity.

Three main categories of processes

The processes are usually divided into three groups:

Core processes

These are the heart of the business and are about meeting customer needs. They generate direct revenue and involve the development and delivery of products or services.

Support processes

These support core processes, even if they don't directly create value. Examples include billing, IT support, and HR.

Management processes

These set strategic direction and govern the business. It can be challenging to separate them from support processes, and a thorough assessment is important for correct classification.

How to create an effective process map

A proven methodology, used among others at 4human QM365 , involves bringing together knowledgeable people from different parts of the organization:

1. Silent brainstorming

Gather a diverse group of employees.

Ask the question: “What is happening in our company?”

Each participant writes key words on post-it notes in silence for about 10 minutes.

2. Sorting and structuring

Place all the notes on a wall or whiteboard.

Group similar notes without discussion (affinity method).

Place management-related notes at the top, support at the bottom, and core processes in the middle.

3. Label the processes

Use action verbs and nouns, such as "remove paint" or "provide quotation", rather than abstract titles such as "Paint removal".

4. Build the process map

A good process map provides a clear and understandable management system.

In our system, you can customize box size, colors, icons, and text, as well as use graphical elements such as arrows and lines to show relationships.

5. Keep it simple

Although the system supports advanced maps, we recommend simplicity and clarity. The maps should be useful for all employees – not just quality managers or certification bodies.

Additional benefits

Our software offers features such as sorting by job roles and responsibilities, so each user only sees relevant information. It can also be adapted to larger organizations and departments, with the ability to include shared processes.

Want to know more?

Simplify and improve your everyday life – book a no-obligation meeting.

Related posts

A guide to quality management trends for 2025

Discover the future of quality management in 2025! The world is changing rapidly, and quality management (QMS) must keep up. New technologies such as...

10 steps to better process flow: A guide for modern businesses

Effective process maps are the key to a good process-driven management system. This guide gives you a practical and easy...

Quality and risk with ISO 9001

In today's dynamic business world, quality and risk are two sides of the same coin. Many companies are already working purposefully to achieve...