Prosesskart

Et godt prosesskart gjør det enkelt for ansatte å får oversikt over virksomheten. Hvordan skal dere gå frem for å tegne et godt prosesskart?

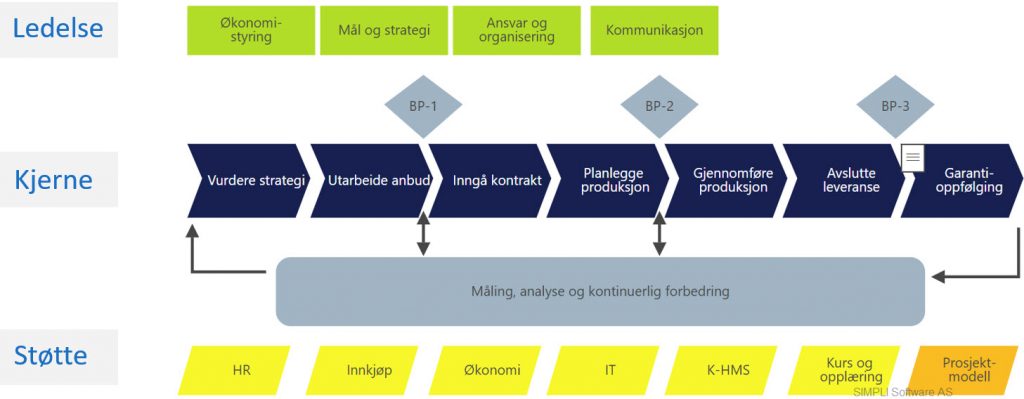

ISO 9001 oppfordrer oss til å jobbe prosessbasert. Utfordringen for de fleste virksomheter blir da å lage oversiktlige prosesskart som alle ansatte lett kjenner seg igjen i. Det er også viktig å enkelt kunne se hva mitt ansvarsområde er, og hvordan dette ansvarsområdet henger sammen med resten av virksomheten.

Først: Hvorfor prosesskart

Et organisasjonskart er en vertikal og funksjonell beskrivelse av virksomheten. Et organisasjonskart sier ikke noe om hva vi gjør, hvem vi gjør det for eller hvordan vi gjør det.

Et prosesskart viser derimot organisasjonen som et system der kunden, produktet og arbeidsflyten henger sammen. Det blir mulig å se hvordan arbeidet virkelig utføres gjennom prosesser som går på tvers gjennom de funksjonelle grensene og avdelingene.

ISO 9001 er meget spesifikk her og krever at man identifiserer prosesser og styrer disse for å oppfylle kunders forventninger. Å styre i henhold til prosesser er derfor nødvendig om man ønsker å inneha en ISO sertifisering og uansett å anbefale.

Å etablere et prosesskart hjelper den ansatte med å se hele produksjonslinjen i stedet for å kun fokusere på å maksimere sine mål internt i egen avdeling.

Prosesskategorier

Kjerneprosess

Støtteprosess

Ledelsesprosess

Prosesskartlegging i praksis

1. Stille brainstorming

2. Lapper opp på veggen:

3. Stille sortering:

4. Sett navn på hver gruppe av lapper.

Å bygget et prosesskart

Et godt prosesskart er et viktig fundament i å bygge opp et enkelt og forståelig styringssystem – uansett man standard man skal implementere, så etter en god prosesskartlegging har dere et godt grunnlag for å bygge opp deres eget grafiske prosesskart. I vårt styringssystem er det gjort enkelt. Det er funksjoner for å designe hver boks som man vil når det kommer til størrelse, farge og ønsket ikon. Du designer også ønsket tekst og realasjon mellom boksene med grafikkelementer som piler og streker.

Selv om den rike funksjonaliteten muliggjør avanserte prosesskart anbefaler vi å gjøre disse kartene så enkle som mulig. Husk at de skal gi verdifull informasjon ikke bare til sertifisør eller kvalitetssjef, men kanskje først og fremst til hver enkelt ansatt.

Da må prosesskartet være enkelt å forstå og enkelt å bruke. Vår programvare har kraftige funksjoner for å koble all relevant informasjon til den enkelte prosess, som for eksempel:

All informasjon på en delprosess er tilgjengelig direkte fra prosesskartet i QM365 Manage.

- Prosessbeskrivelse – dokumentasjon synlig direkte i kartet. (Klikk på bildet for å se en større versjon.)

- Dokumenter – styringsdokumenter, maler og registreringer

- Aktiviteter – ytterligere dokumentsjon i tekstbokser

- Risikoer

- Lover og krav

- Mål

- Lenker til relevante nettsteder og verktøy

I 4human QM365 har vi lang erfaring med å hjelpe våre kunder til å lage enkle og gode prosesskart!